The Ultimate Guide to Finding Reliable Welding Inspection Milwaukee Professionals

The Ultimate Guide to Finding Reliable Welding Inspection Milwaukee Professionals

Blog Article

Comprehending the Significance of Welding Examination in Ensuring Structural Integrity and Safety Across Different Industries

Welding examination is an essential procedure that safeguards architectural honesty and safety across diverse markets. As we discover the complexities of welding inspection, the inquiry occurs: what are the most important factors that contribute to effective examination processes?

Role of Welding Evaluation

While the stability of welded frameworks is extremely important to safety and performance, the function of welding examination can not be overstated. Welding evaluation acts as a critical high quality control process that makes sure the adherence to developed criteria and specifications throughout the welding procedure. By methodically reviewing welds for problems, inconsistencies, and non-compliance, examiners play a vital duty in protecting the integrity of frameworks throughout numerous sectors.

Welding evaluations encompass a series of activities, from pre-weld evaluations to post-weld assessments. These assessments not only identify potential concerns prior to they escalate but additionally improve the overall integrity and lifespan of bonded components. Welding Inspection Milwaukee. Examinations aid to verify the ability and competencies of welders, making certain that welding treatments are implemented correctly and materials are compatible

In addition, a strenuous assessment protocol fosters compliance with governing needs and sector requirements, reducing the danger of devastating failures. By advertising a culture of safety and security and accountability, welding evaluation adds dramatically to both functional and economic performances. In sum, the function of welding examination is essential, as it underpins the high quality, safety and security, and longevity of welded structures vital to modern-day infrastructure and sector.

Sorts Of Welding Assessments

Comprehending the numerous types of welding assessments is necessary for preserving the high quality and safety and security of welded frameworks. Welding assessments can be categorized right into several types, each offering a certain objective in the analysis procedure.

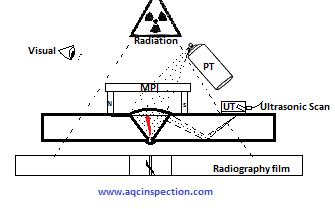

Aesthetic evaluation is one of the most essential kind, involving a mindful exam of the welds with the naked eye or via magnifying. This method aids determine surface problems such as splits, incomplete fusion, or excessive spatter.

These methods allow inspectors to assess the honesty of welds without jeopardizing the product's structure. Ultrasonic testing makes use of high-frequency audio waves to find interior imperfections, while radiographic screening utilizes X-rays or gamma rays to visualize interior weld attributes.

Harmful screening, though less typical, involves physically testing examples to recognize the weld's mechanical buildings. Each sort of assessment adds to a comprehensive assessment, making certain that welding meets industry standards and safety demands.

Sector Requirements and Laws

Developing sector criteria and laws is vital for ensuring the safety and reliability of bonded frameworks. These criteria offer as criteria for performance, safety, and quality, directing producers and inspectors in the implementation of welding procedures. Numerous organizations, such as the American Welding Culture (AWS) and the International Company for Standardization (ISO), have actually established thorough standards that determine treatments for welding practices, qualification of welders, and evaluation methods.

Conformity with these guidelines not just boosts the top quality of welds yet additionally lessens threats related to architectural failings. Certain codes, such as the ASME Central Heating Boiler and Stress Vessel Code, synopsis needs for the construction of stress vessels, ensuring they can hold up against functional anxieties. Additionally, national and regional laws often mandate adherence to these industry requirements, enhancing their importance throughout markets like construction, aerospace, and vehicle manufacturing.

Normal updates to these standards show advancements in modern technology and welding methods, making certain that precaution continue to be relevant. Therefore, a thorough understanding and execution of these standards is vital for welding specialists, cultivating a culture of security and quality in welded frameworks.

Consequences of Poor Inspections

Insufficient examinations can cause extreme effects in the welding sector, weakening the extremely guidelines and criteria made to ensure security and structural honesty. The repercussions of bad examinations can show up in various forms, from immediate safety hazards to long-lasting structural failures. Among one of the most worrying outcomes is the potential for catastrophic crashes, which can result in considerable injury or loss of life. In industries such as aerospace, construction, and production, the implications of low quality welding can compromise entire structures or parts, bring about expensive repairs and extensive downtime (Welding Inspection Milwaukee).

In addition, insufficient examinations can tarnish a company's credibility and outcome in legal consequences, consisting of fines and litigation. Ultimately, the ramifications of poor evaluations prolong beyond individual jobs, impacting industry-wide standards and public perception, thus emphasizing the vital need for efficient and extensive welding assessments.

Ideal Practices for Effective Assessments

Effective welding examinations are critical to making sure the stability and safety of bonded structures. To achieve optimum results, inspectors must abide by a number of best techniques that boost the assessment process.

Second of all, examiners ought to possess the necessary certifications and accreditations pertinent to the welding processes and materials being taken a look at. Continuous training and expert advancement are essential to remaining updated on sector standards and technical developments.

Furthermore, utilizing appropriate assessment devices and strategies, such as aesthetic inspections, ultrasonic testing, and radiographic assessments, is vital for detecting problems that can compromise structural integrity.

Last but not least, extensive documents of the examination procedure is necessary. This includes recording findings, pictures, and any kind of rehabilitative actions taken. Clear and exact coverage not only promotes responsibility but likewise aids in future evaluations and maintenance. By carrying out these finest practices, organizations can substantially improve the effectiveness of their welding examinations and ensure secure, dependable operations.

Final Thought

To conclude, welding inspection is essential read this article for keeping structural honesty and safety throughout different industries. By methodically reviewing welds and sticking to well-known standards, the evaluation process reduces threats related to problems and non-compliance. The application of best methods in welding examinations not just boosts the reliability and lifespan of bonded parts however also supports industry regulations. As a result, focusing on efficient welding inspections is essential to ensure the security of employees, properties, and total functional stability.

As we discover the ins and outs of welding assessment, the question occurs: what are the most essential aspects that add to efficient evaluation procedures?

Welding assessment offers as an essential high quality control process that makes sure the adherence to established standards and specifications throughout the welding operation. In amount, the function of welding inspection is essential, as it underpins the high quality, safety, and longevity of bonded structures important to modern-day framework and market.

Different companies, such as the American Welding Society (AWS) and the International Organization for Standardization (ISO), have actually established comprehensive standards that dictate treatments for welding techniques, qualification of welders, and assessment methods.

Inevitably, the ramifications of poor examinations prolong beyond specific tasks, influencing industry-wide criteria and public understanding, try this site therefore stressing the vital need for effective and extensive welding examinations.

Report this page